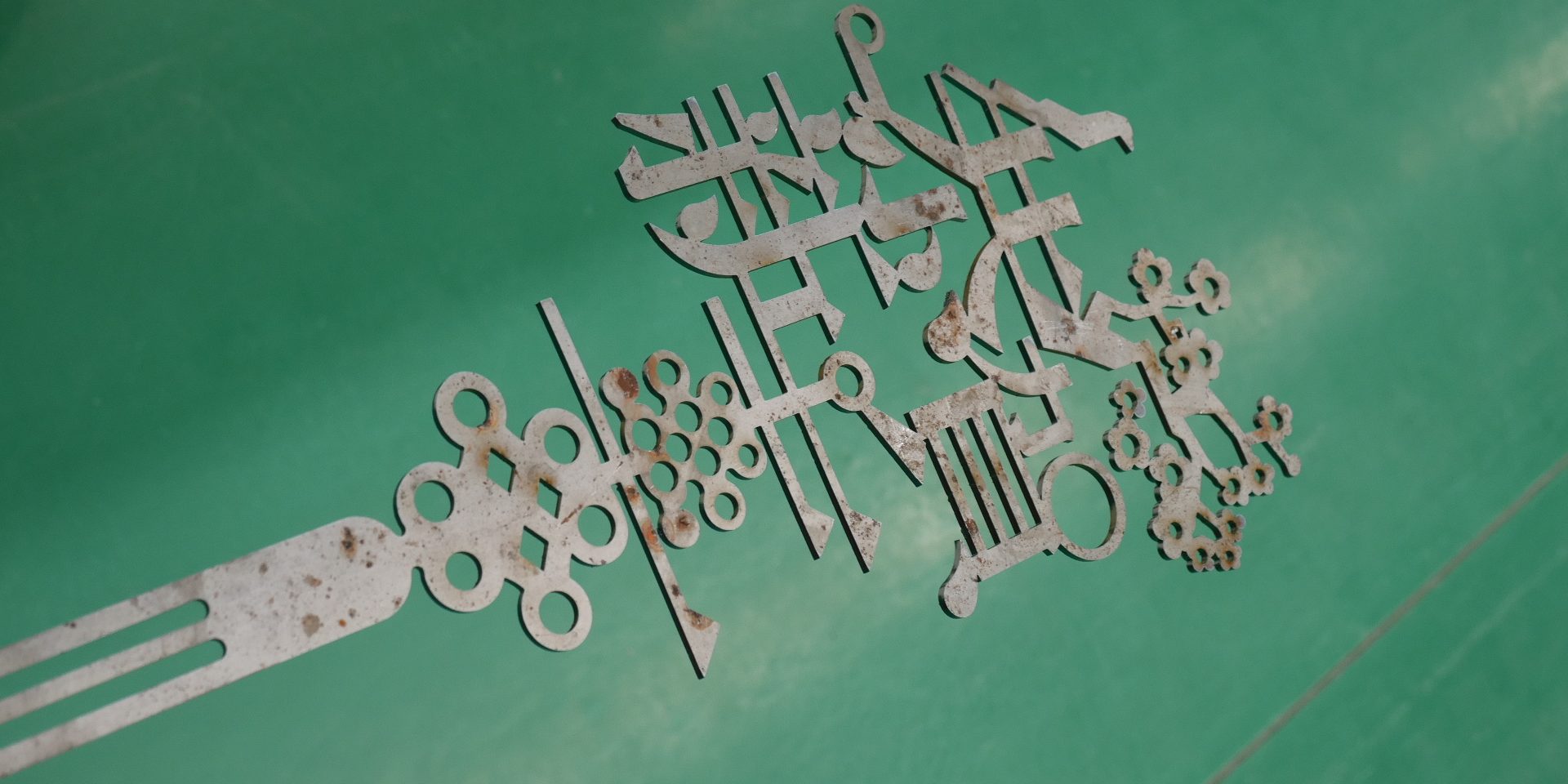

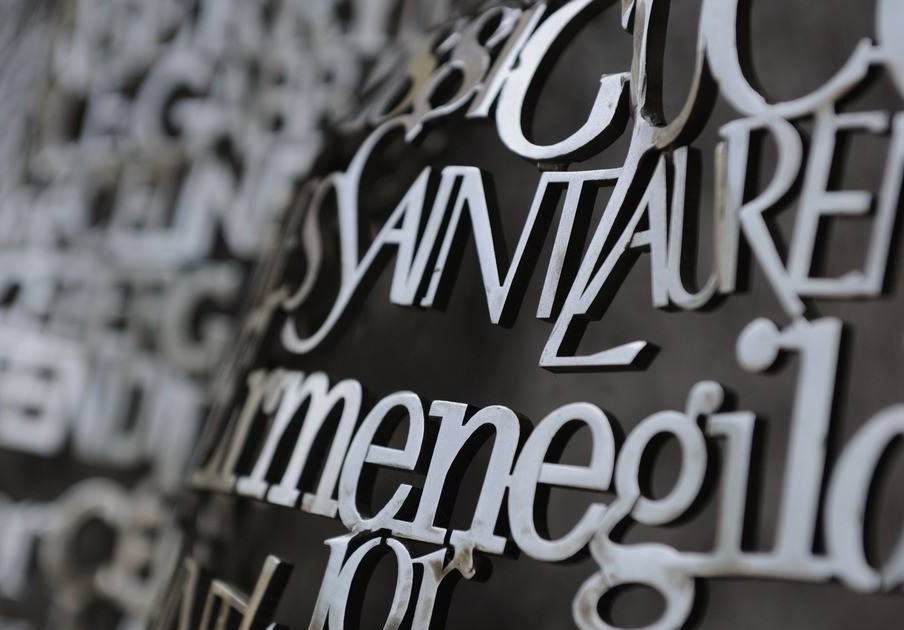

Metal sheet and stainless steel is massively used in different manufacturing business. Fiber Laser cutting machine (Fiber Laser cutter) has quite a lot advantages compare with the old ways .

But how to set the metal sheet laser cutter and stainless steel laser cutter during the manufacturing process , let’s find out together .

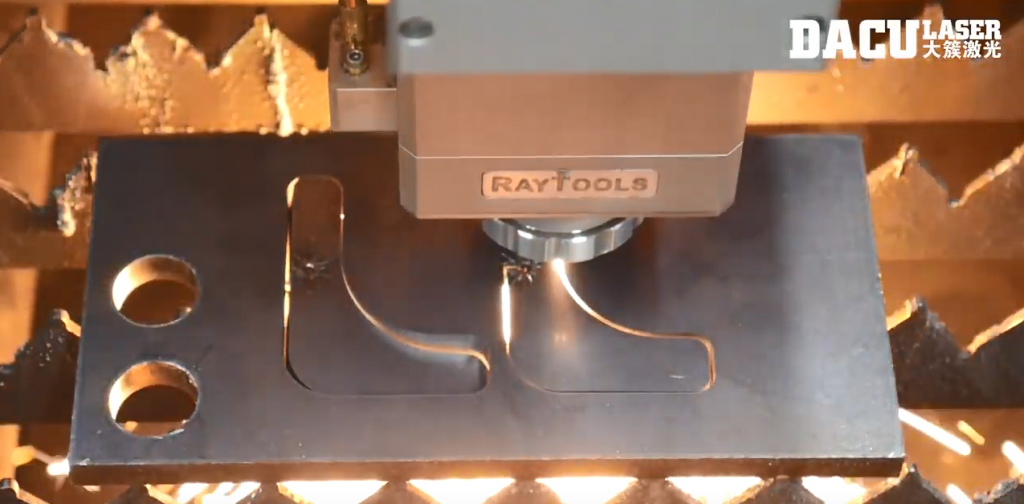

The basic idea behind the laser cutting machine / cutter is use the high engergy beam(Laser Source) as a knife , melt down the materail and use the gas from the laser head to blow down the melted metal . Equipped with CNC router , so that the laser cutters can cut whatever the operator let them to cut.

Laser beam is sort of light with high energu in it , imagine laser head as a camera glass , we need to use different lense in front of the laser head to foucs the laser beam onto the metal sheet or stainless steel , therefore we can concentrate the full output on the cutting surface.

Here are some standard cutting settings in general laser cutting machine include Dacu Laser Cutting machin / Dacu Laser Cutters :

Laser cutting machine for cutting stainless steel:

1) Below 1.0—1.5 stainless steel is cut with 1.4-2.0 double-layer cutting tip, compensation value is 0.1, defocus amount is -1

2) 2.0 stainless steel is cut with a 2.0 double-layer cutting tip, the compensation value is 0.15, and the defocus amount is -1.5-2.0.

3) 3.0 stainless steel is cut with a 2.0-2.5 double-layer cutting tip, the compensation value is 0.2, and the defocus amount is -2.5-3.0.

4) The 4.0 stainless steel is cut with a 2.5-3.0 double-layer cutting tip, the compensation value is 0.2, and the defocus amount is -3.5-4.0.

5) 5.0 stainless steel is cut with a 2.5-3.0 double-layer cutting tip, the compensation value is 0.25, and the defocus amount is -4.5-5.0.

6) 6.0 stainless steel is cut with a 3.0-3.5 double-layer cutting tip, the compensation value is 0.3, and the defocus amount is -5.0-5.5.

7) 8.0 stainless steel is cut with a 3.5-4.0 single-layer cutting tip, the compensation value is 0.3, and the defocus amount is -6.5-7.0.

8) 10.0 stainless steel is cut with a 4.0-4.5 single-layer cutting tip, the compensation value is 0.35, and the defocus amount is -7.0-7.5.

9) 12.0 stainless steel is cut with a 4.5 single-layer cutting tip, the compensation value is 0.4, and the defocus amount is -8.0-9.0.

Laser cutting machine cutting carbon steel:

1) For 1MM carbon steel cutting, use 1.0 and 1.4 double-layer cutting tips to cut the compensation value to 0.25 and the defocus amount to 3.0.

2) For 2MM carbon steel cutting, use 1.0 and 1.4 double-layer cutting tips to cut compensation value 0.3 and defocus amount 3.0.

3) For 3.0MM carbon steel, use 1.0 and 1.4 double-layer cutting tips to cut compensation value 0.3 and defocus amount 3.0.

4) For 4.0MM carbon steel, 1.0 and 1.4 double-layer cutting tips are used to cut the compensation value to 0.3 and the defocus amount to 2.5.

5) 5.0 MM carbon steel uses 1.0 and 1.4 double-layer cutting tips to cut compensation value 0.3 and defocus amount 2.5.

6) 6.0 MM carbon steel uses 1.0 and 1.4 double-layer cutting tips to cut compensation value 0.3 and defocus amount 2.5.

7) 7.0 MM carbon steel uses 1.0 and 1.4 double-layer cutting tips to cut compensation value 0.3 and defocus amount 2.5.

8) 8.0 MM carbon steel uses 2.5 and 3.0 double-layer cutting tips to cut compensation value 0.3 and defocus amount 3.0.

9) 10.0MM carbon steel uses 2.5 and 3.0 double-layer cutting tips to cut compensation value of 0.35 and defocus amount of 3.0.

10) 12.0MM carbon steel uses 3.0 and 3.5 double-layer cutting tips to cut compensation value of 0.4 and defocus amount of 3-3.5.

11) 14.0MM carbon steel uses 3.0 and 3.5 double-layer cutting tips to cut compensation value of 0.45 and defocus amount of 3-3.5.

12) For 16.0MM carbon steel, use 3.5 and 4.0 double-layer cutting tips to cut the compensation value by 0.5 and the defocus amount by 3-3.5.

13) 20.0MM carbon steel with 3.5, 4.0, 4.5 double-layer cutting nozzle cutting compensation value 0.7, defocus amount 3.5-4.0.

Use these settings during your operation to maximize your benifit.